Rapid Delivery for Ceramic Wear - Wholesale custom nonstandard metal worm gears bevel gears pinion gears – Zhongfu

Rapid Delivery for Ceramic Wear - Wholesale custom nonstandard metal worm gears bevel gears pinion gears – Zhongfu Detail:

- Condition:

-

New

- Warranty:

-

Unavailable

- Shape:

-

Spur

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

Not Available

- Core Components:

-

Gear

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Material:

-

Steel, Tungsten Carbide

- Product name:

-

gears

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- shape:

-

supr

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Advantage:

-

High Wear Resistance

- Quality:

-

Top High

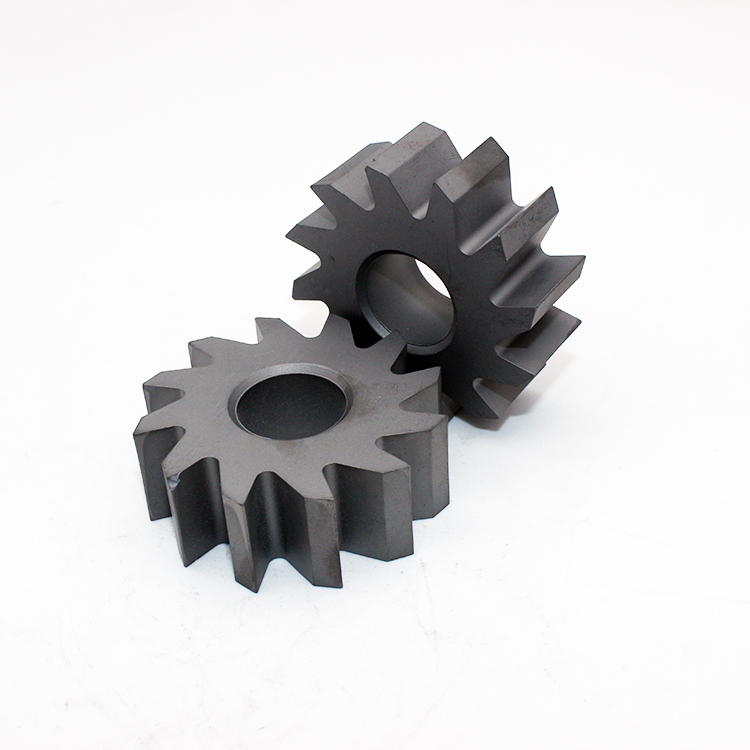

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

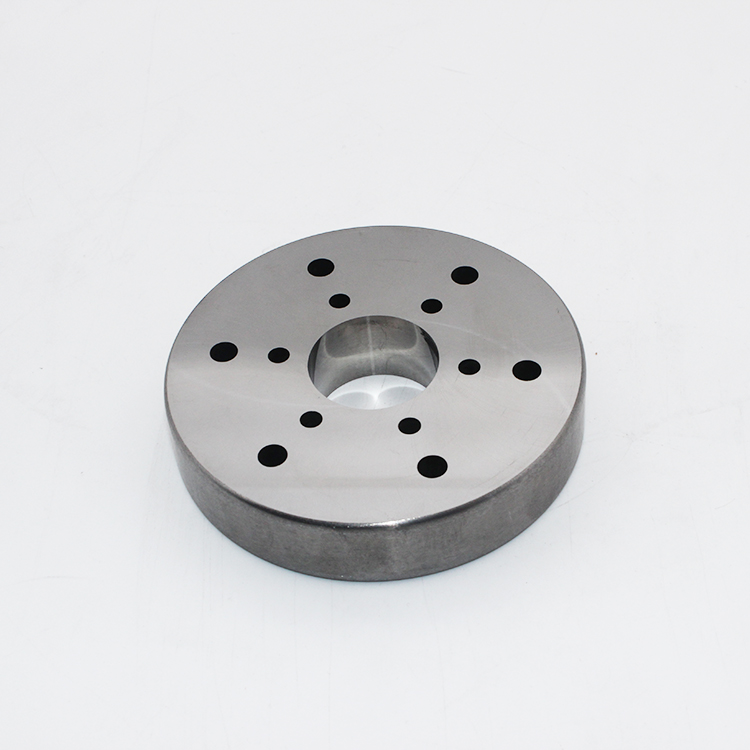

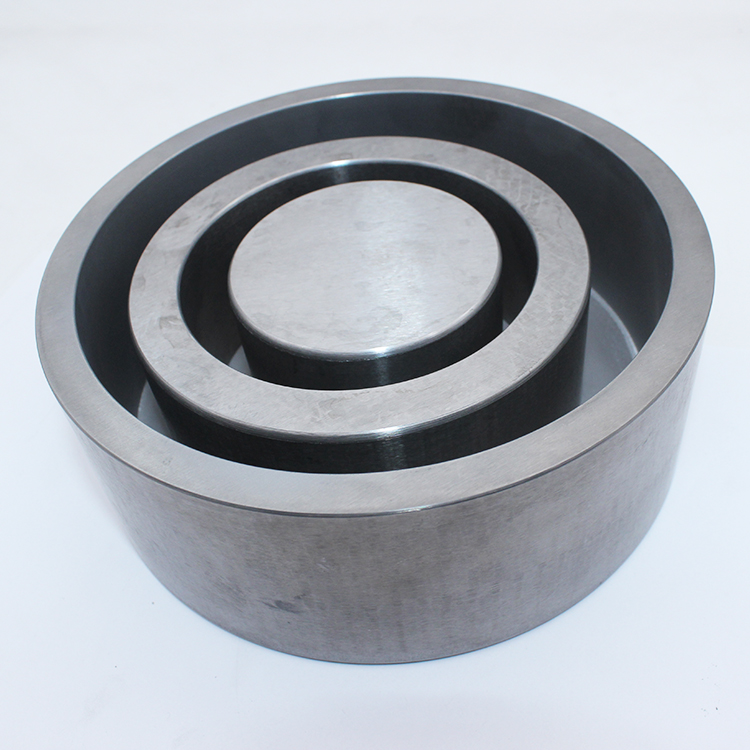

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Rapid Delivery for Ceramic Wear - Wholesale custom nonstandard metal worm gears bevel gears pinion gears – Zhongfu , The product will supply to all over the world, such as: Morocco, Puerto Rico, Philadelphia, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

Along with the “Client-Oriented” small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for OEM/ODM China China Cutting Tools Vnmg160408 Tungsten Carbide Insert CNC Turning Insert for Stainless Steel, As a key business of this industry, our company makes endeavours to become a leading supplier, based on the faith of specialist quality & throughout the world company.

OEM/ODM China China Cutting Tool, Insert Turning Tools, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we’ve gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

We know that we only thrive if we could guarantee our combined selling price competiveness and good quality advantageous at the same time for Competitive Price for China Cheap Price Good Quality PVD CVD Coating Hard Alloy Spmg-Sg Us Tungsten Carbide Drilling Inserts, Our experienced complex workforce might be wholeheartedly at your support. We sincerely welcome you to definitely stop by our web site and company and mail us your inquiry.

Competitive Price for China Drill Inserts, Wc08, With the development of the society and economy, our company will continue the “loyalty, dedication, efficiency, innovation” spirit of enterprise, and we’ll always adhere to the management idea of “would rather lose gold, do not lose customers heart”. We’ll serve the domestic and foreign businessmen with sincere dedication, and allow us to create bright future together with you!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!