professional factory for Od Grinding Services - New Shape Tungsten Carbide Tamping Tine Tools for Railway Industry – Zhongfu

professional factory for Od Grinding Services - New Shape Tungsten Carbide Tamping Tine Tools for Railway Industry – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

PETORY

- Model Number:

-

tamping tines for railway

- Product name:

-

tamping tines

- Usage:

-

for railway

- leadtime:

-

in stock

- Grade:

-

YG9C

- Size:

-

Customized Size

- Color:

-

Silver Black

- Service:

-

ODM OEM

- Certification:

-

ISO 9001

- Samples:

-

Avaliable

- Packing:

-

Box

|

Item

|

Tungsten carbide tamping tines

|

|

Sizes

|

customized or standard

|

|

Country of Origin

|

Jiangxi, China

|

|

Usage

|

Tungsten carbide tamping tool, tamping pick

|

Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

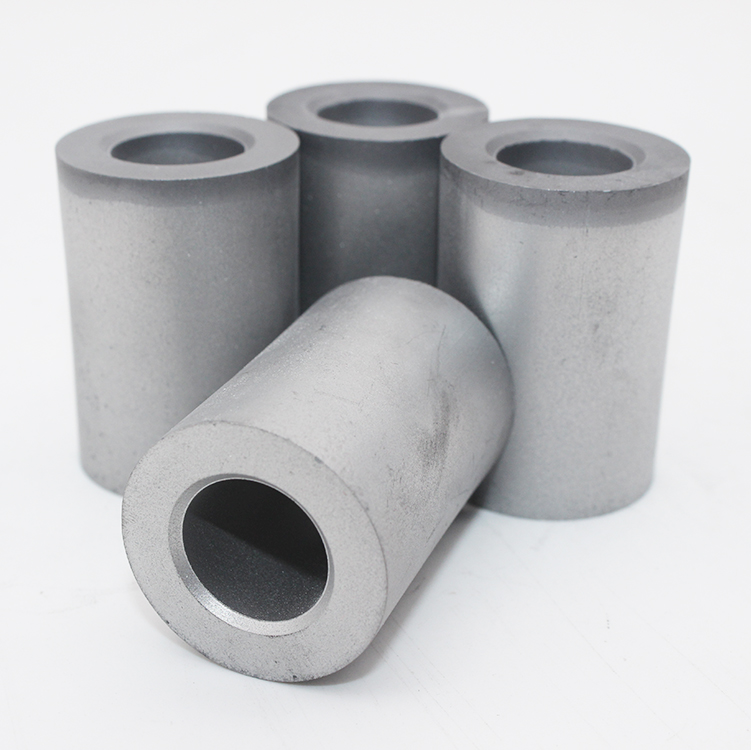

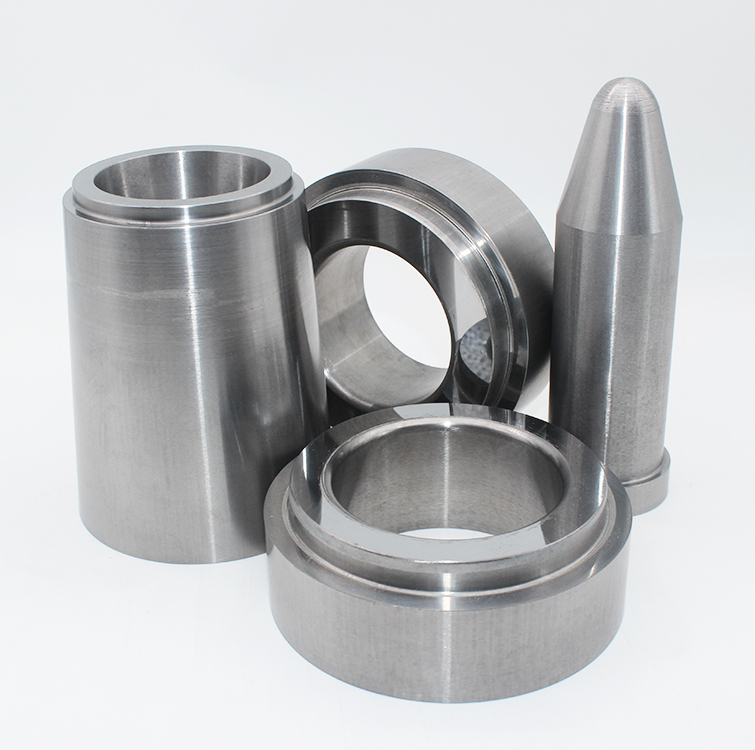

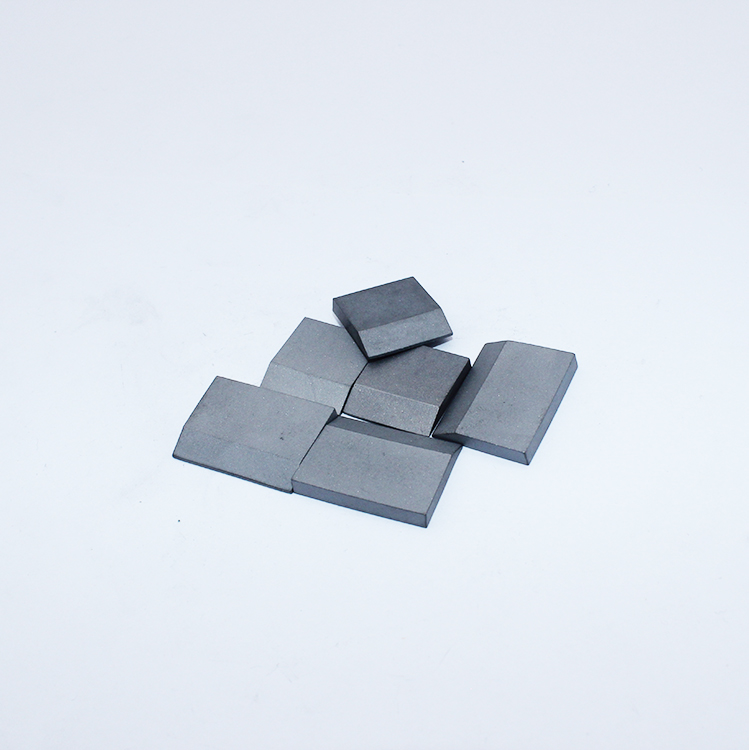

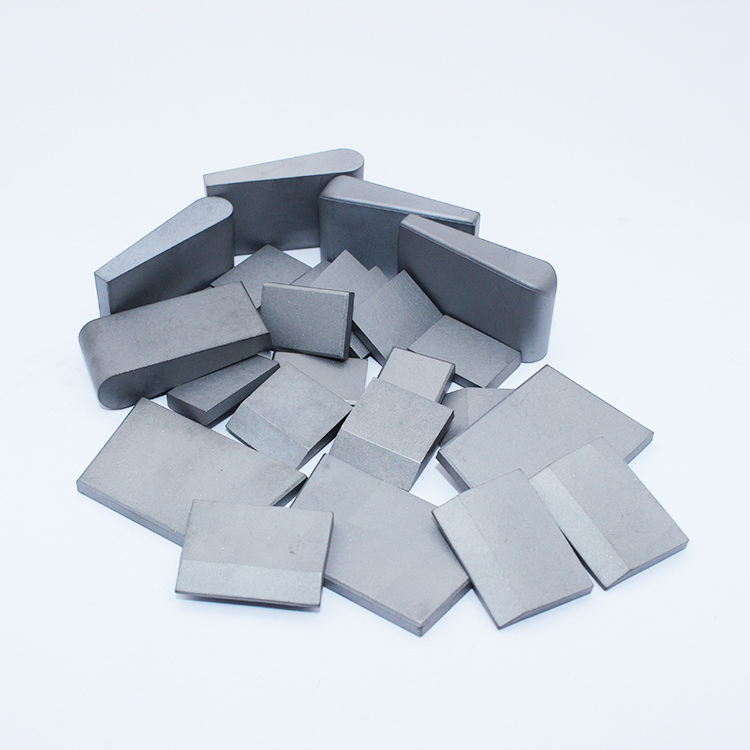

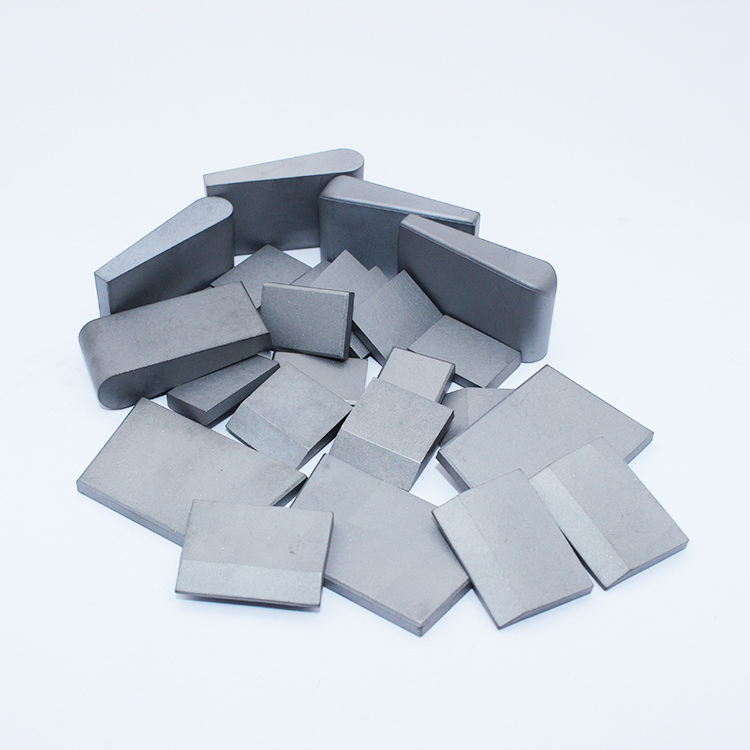

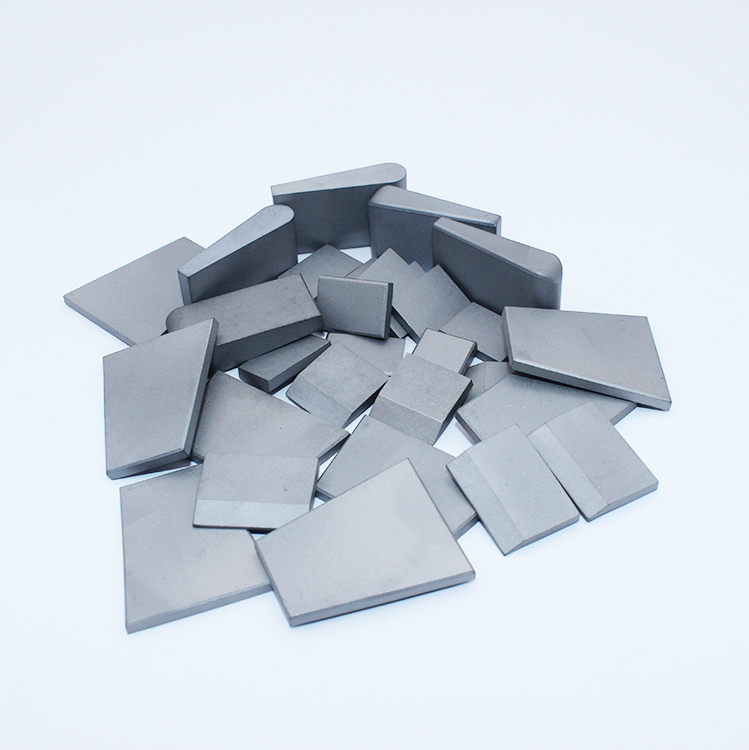

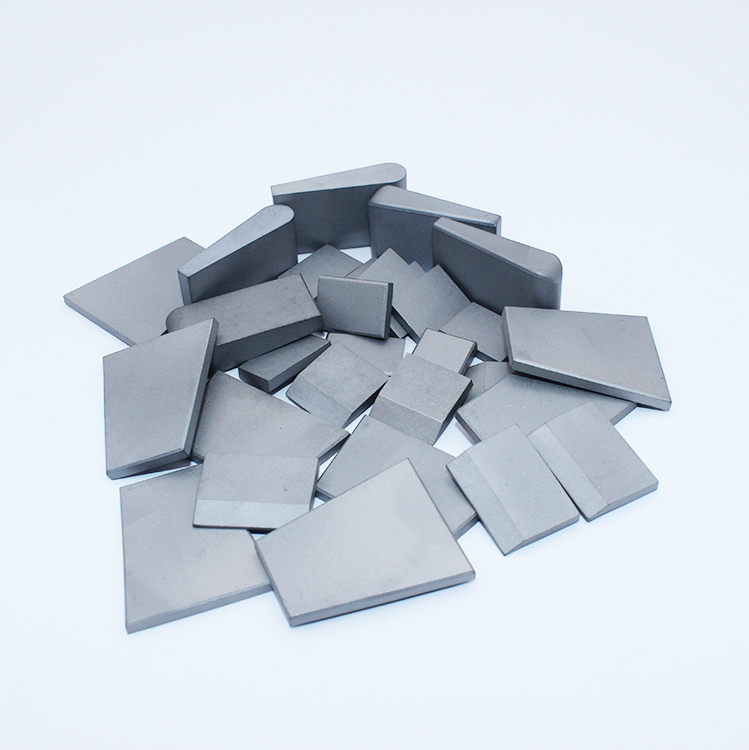

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for professional factory for Od Grinding Services - New Shape Tungsten Carbide Tamping Tine Tools for Railway Industry – Zhongfu , The product will supply to all over the world, such as: Dominica, Singapore, Paris, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.