Professional China Tungsten Carbide Parts Manufacturers - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu

Professional China Tungsten Carbide Parts Manufacturers - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Model Number:

-

scarifier cutters

- Material:

-

Carbide, Tungsten Carbide

- Coating:

-

Tin

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- Types of CNC Cutting Tools:

-

scarifier cutters

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Quality:

-

Top High

- Packing:

-

Wood

- Advantage:

-

High Wear Resistance

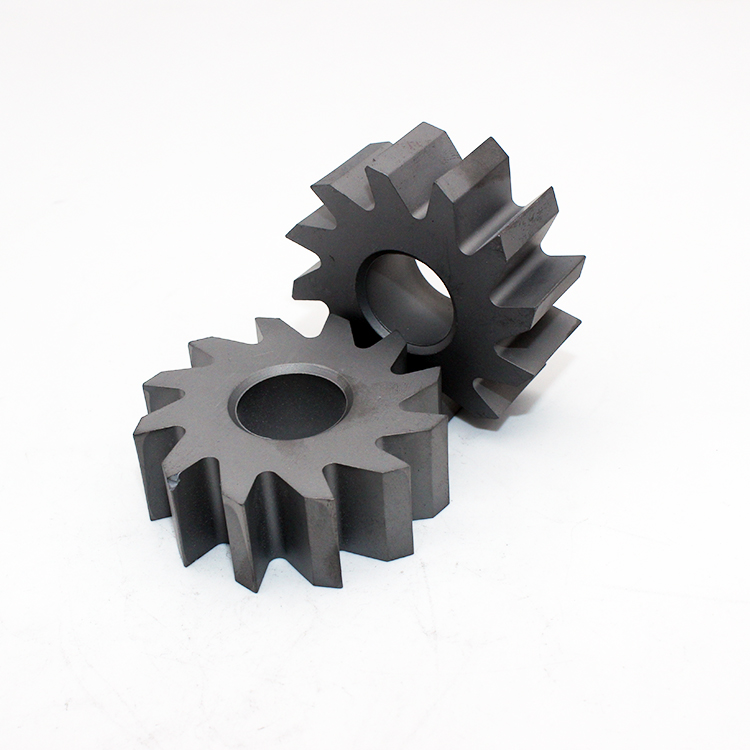

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

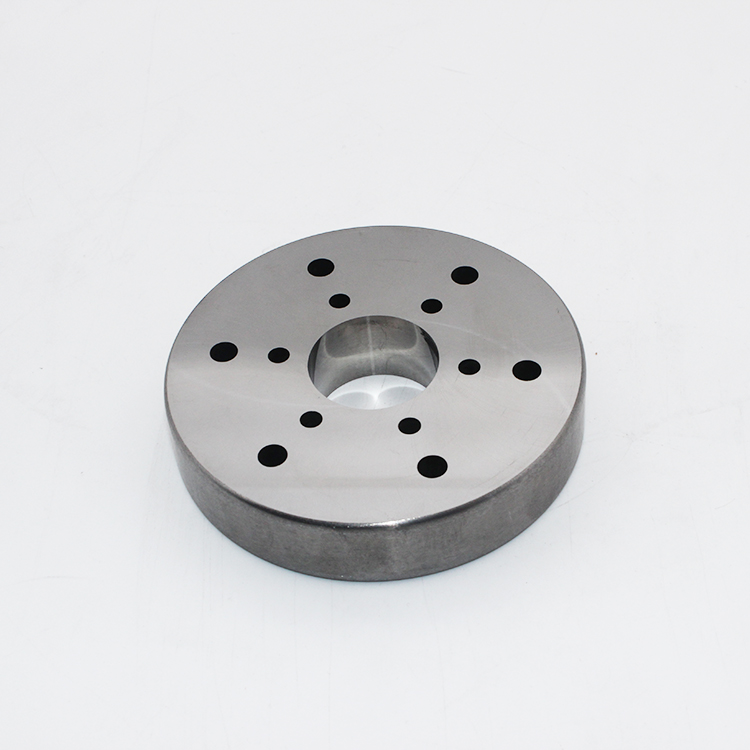

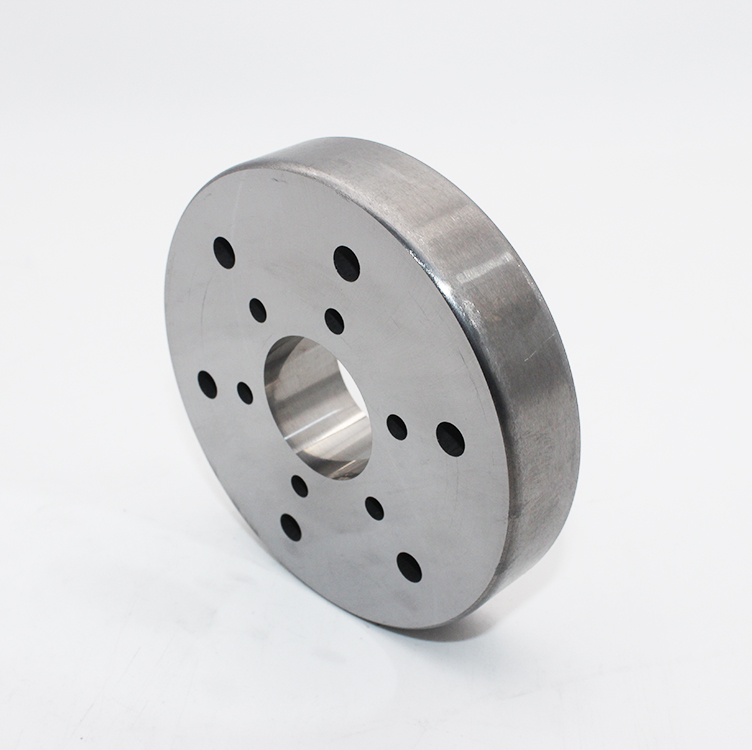

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for Professional China Tungsten Carbide Parts Manufacturers - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu , The product will supply to all over the world, such as: Rotterdam, Finland, Frankfurt, We now have to continue to uphold the "quality, detailed, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

“Quality initial, Honesty as base, Sincere assistance and mutual profit” is our idea, as a way to produce continuously and pursue the excellence for Price Sheet for China Custom Size Shaping Mode Punching Mold Tungsten HSS Mould Punch Carbide Pins CNC Machining Parts, We welcome new and old customers to contact us by phone or send us inquiries by mail for future business relationships and achieving mutual success.

Price Sheet for China DIN9861, DIN1530, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, remember to feel free to contact us for quotation and product details.

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Reasonable price for China Custom CNC Turning Milling Metal Precision Machined/ Machining Parts for Carbide Inserts, Any interest, remember to really feel absolutely free to make contact with us. We’re hunting forward to forming prosperous small business relationships with new consumers within the environment while in the in the vicinity of long term.

Reasonable price for China CNC Turning Machining, Machining Part, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the goods performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!