Original Factory Mining Bits - Wholesale custom nonstandard metal worm gears bevel gears pinion gears – Zhongfu

Original Factory Mining Bits - Wholesale custom nonstandard metal worm gears bevel gears pinion gears – Zhongfu Detail:

- Condition:

-

New

- Warranty:

-

Unavailable

- Shape:

-

Spur

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

Not Available

- Core Components:

-

Gear

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

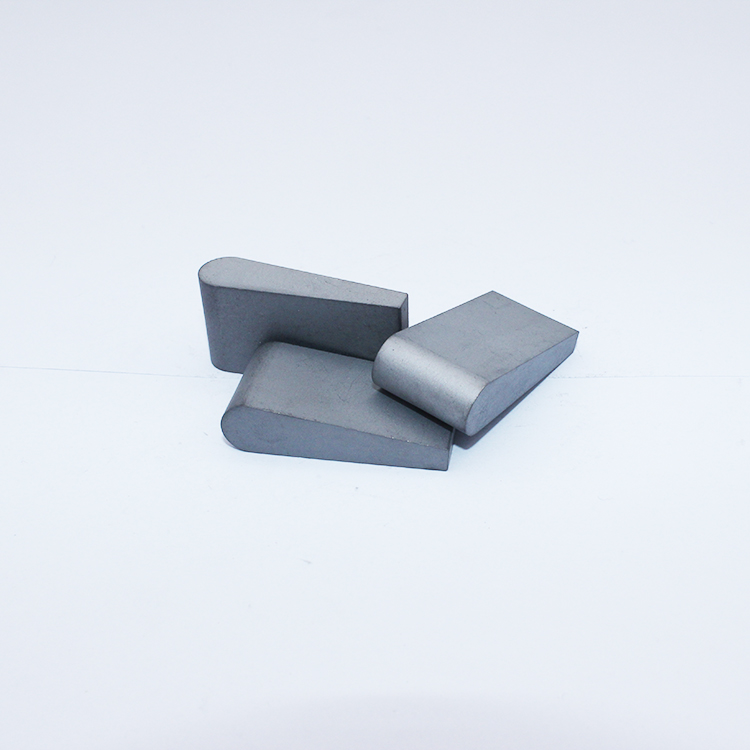

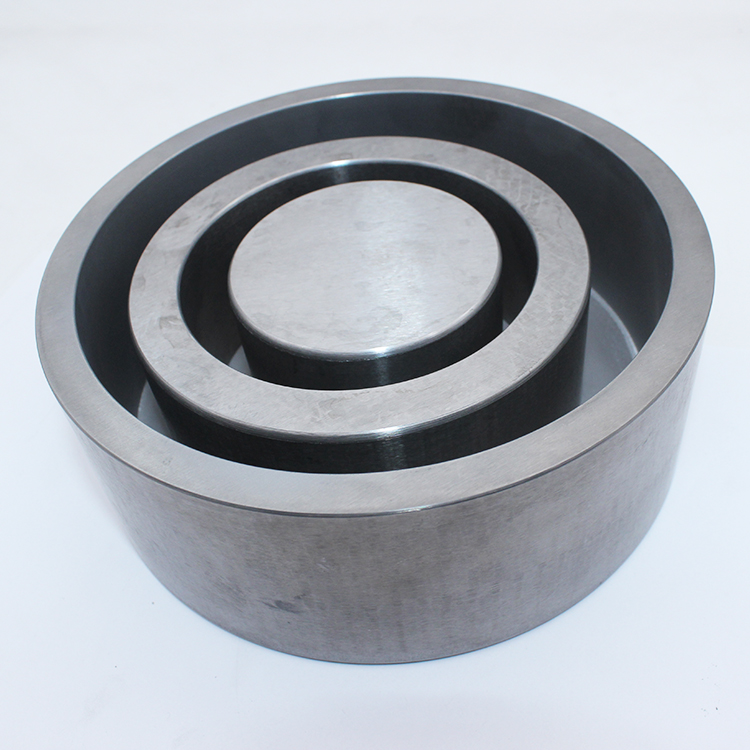

- Material:

-

Steel, Tungsten Carbide

- Product name:

-

gears

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- shape:

-

supr

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Advantage:

-

High Wear Resistance

- Quality:

-

Top High

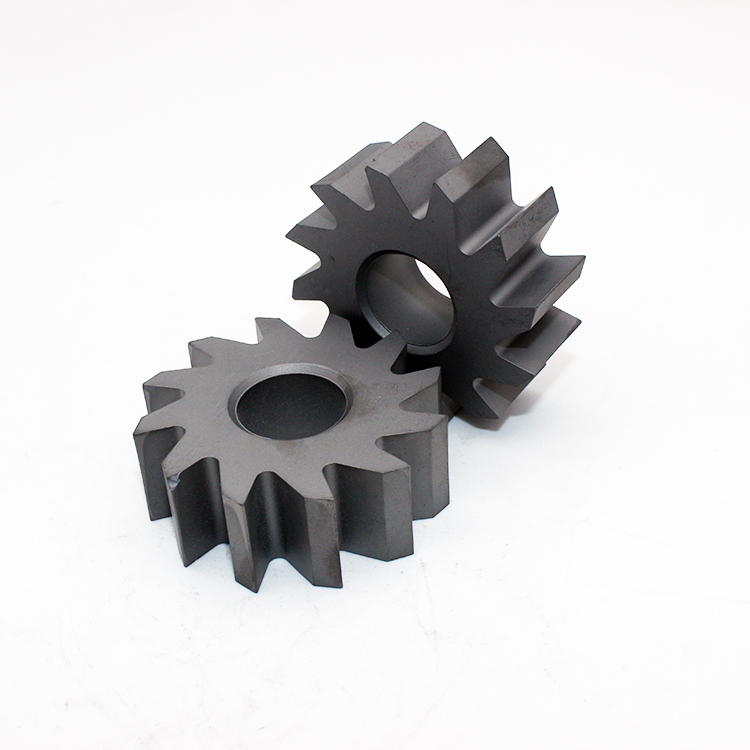

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

Product detail pictures:

Related Product Guide:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Original Factory Mining Bits - Wholesale custom nonstandard metal worm gears bevel gears pinion gears – Zhongfu , The product will supply to all over the world, such as: Serbia, Mexico, Hungary, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

“Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for OEM Manufacturer China CNC Lathe Machines Tungsten Carbide Inserts for Lathe Machine, We now have exported to far more than 40 countries and regions, which have gained very good reputation from our costumers everywhere in the entire world.

OEM Manufacturer China Carbide Inserts, Inserts, For anyone who is keen on any of our items right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it’s easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We’re always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Our solutions are broadly identified and trusted by buyers and might fulfill continuously changing economic and social wants of Best Price on China Shoulder Milling Cutter Tungsten Carbide Inserts with High Efficient Processing, If you pursuit the Hi-quality, Hi-stable, Competitive price parts, company name is your best choice!

Best Price on China Tungsten Carbide Insert, Tungsten Carbide, Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.