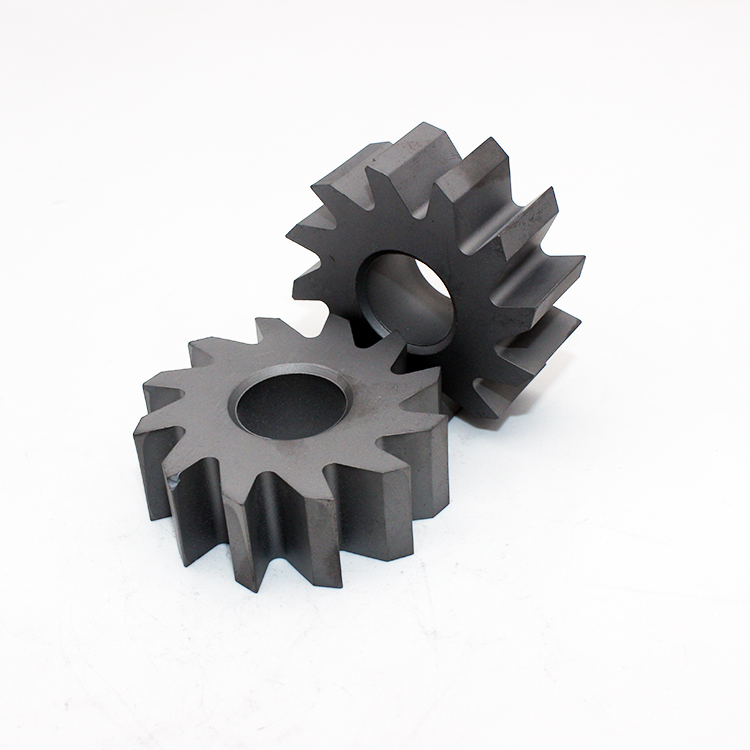

OEM/ODM Manufacturer Can Tungsten Carbide Be Cut - Customize good quality precision metal parts spur gear tiller cultivator parts back gear – Zhongfu

OEM/ODM Manufacturer Can Tungsten Carbide Be Cut - Customize good quality precision metal parts spur gear tiller cultivator parts back gear – Zhongfu Detail:

- Condition:

-

New

- Warranty:

-

Unavailable

- Shape:

-

Spur

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

Not Available

- Core Components:

-

Gear

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Material:

-

Steel, Tungsten Carbide

- Product name:

-

gears

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- shape:

-

supr

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Advantage:

-

High Wear Resistance

- Quality:

-

Top High

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for OEM/ODM Manufacturer Can Tungsten Carbide Be Cut - Customize good quality precision metal parts spur gear tiller cultivator parts back gear – Zhongfu , The product will supply to all over the world, such as: Singapore, Amsterdam, Ecuador, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The corporate upholds the philosophy of “Be No.1 in high quality, be rooted on credit history and trustworthiness for growth”, will continue to serve previous and new customers from home and overseas whole-heatedly for Wholesale Discount China Cnmg120408 Tungsten Carbide CNC Turning Tool Carbide Indexable Insert CNC Turning Inserts Carbide Tool for Steel Lathe Inserts Cutting Turning Tool, We have ISO 9001 Certification and qualified this product or service .in excess of 16 years experiences in manufacturing and designing, so our goods featured with very best high-quality and aggressive rate. Welcome cooperation with us!

Wholesale Discount China Indexable Inserts, Tungsten Carbide Inserts, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We’re making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Our organization sticks for the principle of “Quality will be the life of your business, and name may be the soul of it” for Super Purchasing for China High Precision Auto Tungsten Carbide Insert, With all the tenet of “faith-based, customer first”, we welcome purchasers to simply call or e-mail us for cooperation.

Super Purchasing for China Tungsten Carbide, Carbide Insert, Now we have won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.