OEM Manufacturer Cemented Carbide Vs Tungsten Carbide - Factory wholesale custom tungsten carbide spiral bevel gear milling cutters for sale – Zhongfu

OEM Manufacturer Cemented Carbide Vs Tungsten Carbide - Factory wholesale custom tungsten carbide spiral bevel gear milling cutters for sale – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Model Number:

-

scarifier cutters

- Material:

-

Carbide, Tungsten Carbide

- Coating:

-

Tin

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- Types of CNC Cutting Tools:

-

scarifier cutters

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Quality:

-

Top High

- Packing:

-

Wood

- Advantage:

-

High Wear Resistance

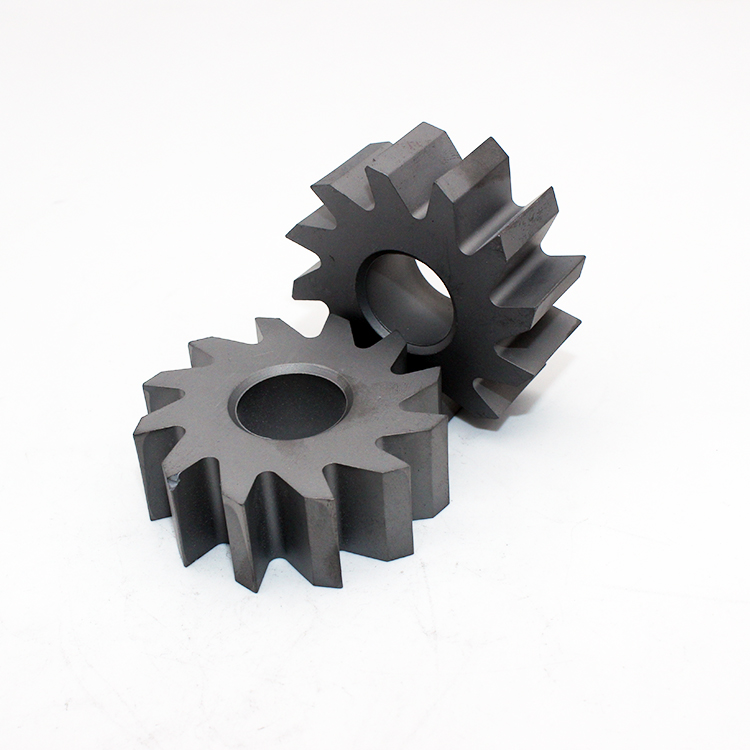

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

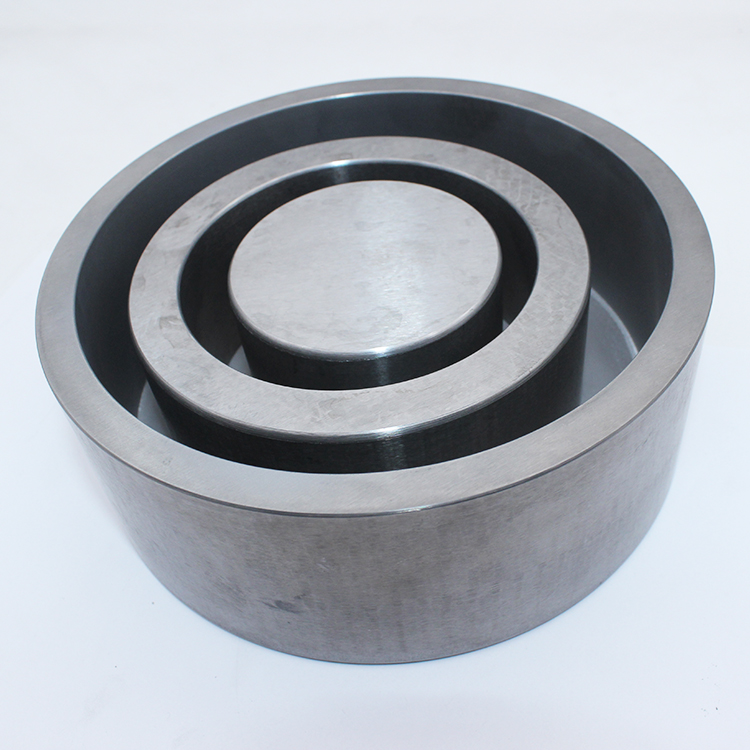

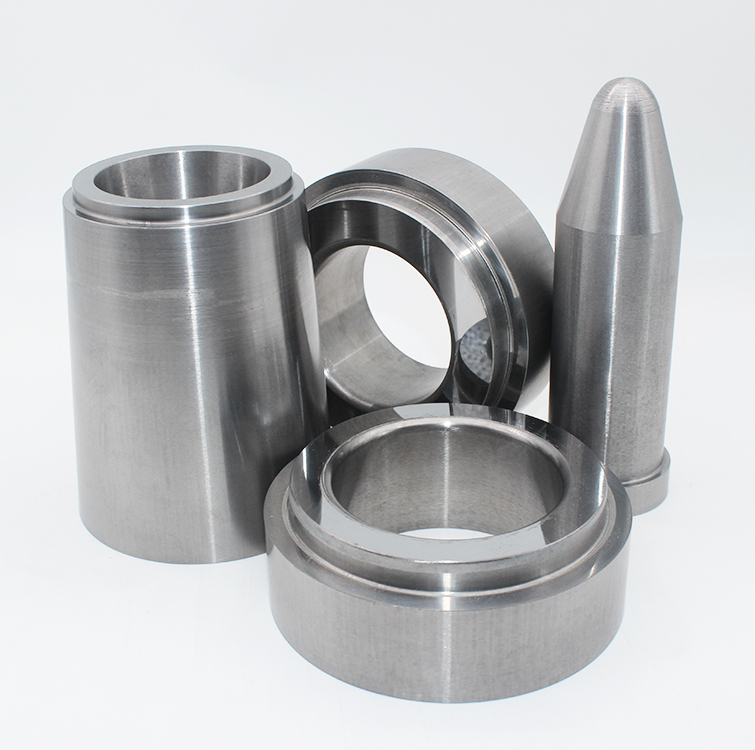

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we've acquired rich practical working experience in producing and managing for OEM Manufacturer Cemented Carbide Vs Tungsten Carbide - Factory wholesale custom tungsten carbide spiral bevel gear milling cutters for sale – Zhongfu , The product will supply to all over the world, such as: Czech, Kyrgyzstan, Kyrgyzstan, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our experienced advice and service can lead to more suitable choice for the customers.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for Professional Design China Gw Carbide, We warmly welcome company companions from all walks of daily life, hope to establish pleasant and cooperative small business call along with you and reach a win-win goal.

Professional Design Tungsten Carbide Milling Inserts Wnmg080408, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to deliver the high-quality products and solutions and services, and promote lasting cooperation with our customers, common development and create a better future.

With our prosperous working experience and thoughtful solutions, now we have been regarded to be a dependable supplier for lots of intercontinental prospective buyers for Wholesale China Low Price Wholesale CNC Turning Tool Tungsten Carbide Inserts Tnmg160408-Mpf, Our experienced specialized group will be wholeheartedly at your support. We sincerely welcome you to check out our site and enterprise and send out us your inquiry.

Wholesale China Turning Insert, Turning Insert (Negative), We believe with our consistently excellent service you can get the best performance and cost least solutions from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

Sticking to your principle of “Super Good quality, Satisfactory service” ,We are striving to get a fantastic business enterprise partner of you for OEM/ODM Supplier China Tungsten Carbide Inserts for Chuck Jaw, We think this sets us apart from the competition and makes prospects choose and trust us. We all wish to build win-win deals with our customers, so give us a call today and make a new friend!

OEM/ODM Supplier China Jaw, Chuck Jaw, We’ve more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information remember to do no hesitate to contact us..

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.