Manufactur standard Tungsten Carbide End Mill - Custom 60 knife variable speed fixed gear cast iron truck large metal gear – Zhongfu

Manufactur standard Tungsten Carbide End Mill - Custom 60 knife variable speed fixed gear cast iron truck large metal gear – Zhongfu Detail:

- Condition:

-

New

- Warranty:

-

Unavailable

- Shape:

-

Spur

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms

- After Warranty Service:

-

No service

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

Not Available

- Core Components:

-

Gear

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Material:

-

Steel, Tungsten Carbide

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- shape:

-

Spur

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Quality:

-

Top High

- Packing:

-

Wood

- Advantage:

-

High Wear Resistance

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

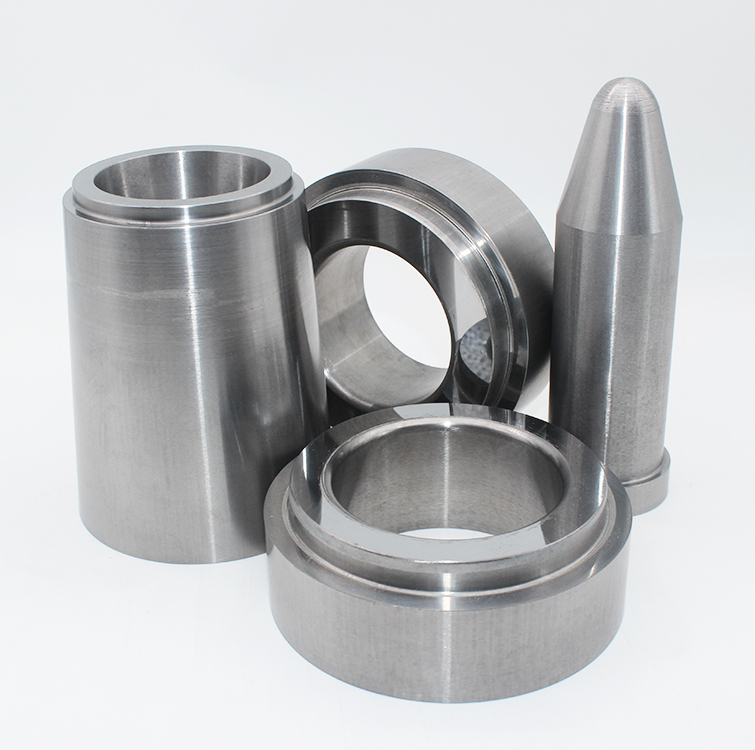

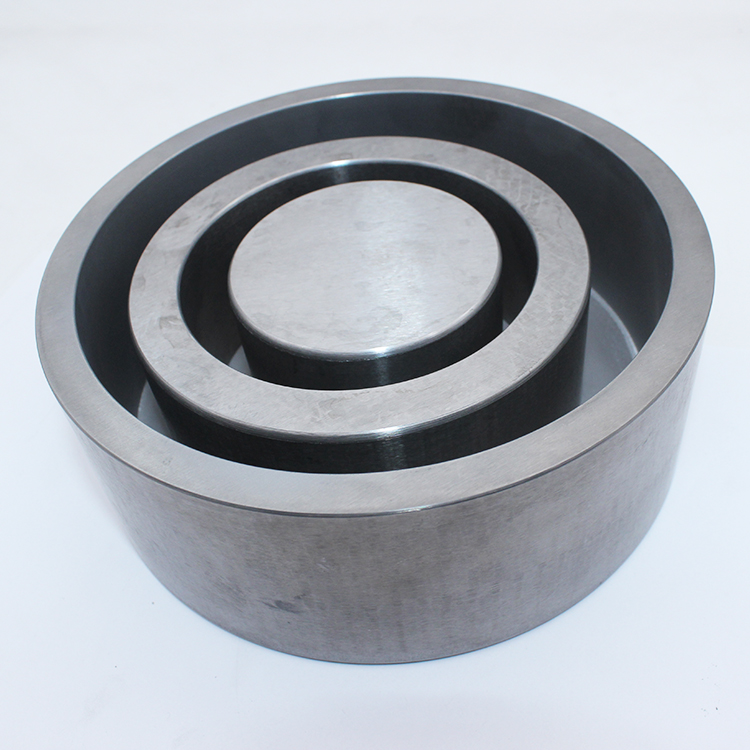

Product detail pictures:

Related Product Guide:

We persistently execute our spirit of ''Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for Manufactur standard Tungsten Carbide End Mill - Custom 60 knife variable speed fixed gear cast iron truck large metal gear – Zhongfu , The product will supply to all over the world, such as: Sudan, Mauritania, Colombia, Relying on superior quality and excellent post-sales, our products sell well in America, Europe, the Middle East and South Africa. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for One of Hottest for China Water Meter Spare Parts Tungsten Shaft, Teamwork is encouraged at all levels with regular campaigns. Our research group experiments on various developments inside the industry for improvement in the merchandise.

One of Hottest for China Water Meter, Water Meter Parts, We follow up the career and aspiration of our elder generation, and we have been eager to open up a new prospect in this field, We insist on “Integrity, Profession, Win-win Cooperation”, because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Good Quality China M7160X16 -600X1600mm Hot Sale Heavy Duty Hydraulic Automatic Surface Grinding Machine, And there are also a lot of overseas close friends who came for sight seeing, or entrust us to buy other stuff for them. You will be most welcome to come to China, to our city and to our manufacturing facility!

Good Quality China Flat Grinder Machine, High Precision, You should truly feel free to send us your requirements and we are going to respond to you asap. We’ve got a specialist engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for yourself personally to understand much more information. In an effort to meet your requires, you should actually feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd products. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.