Manufactur standard Internal Scarfing - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu

Manufactur standard Internal Scarfing - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Model Number:

-

scarifier cutters

- Material:

-

Carbide, Tungsten Carbide

- Coating:

-

Tin

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- Types of CNC Cutting Tools:

-

scarifier cutters

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Quality:

-

Top High

- Packing:

-

Wood

- Advantage:

-

High Wear Resistance

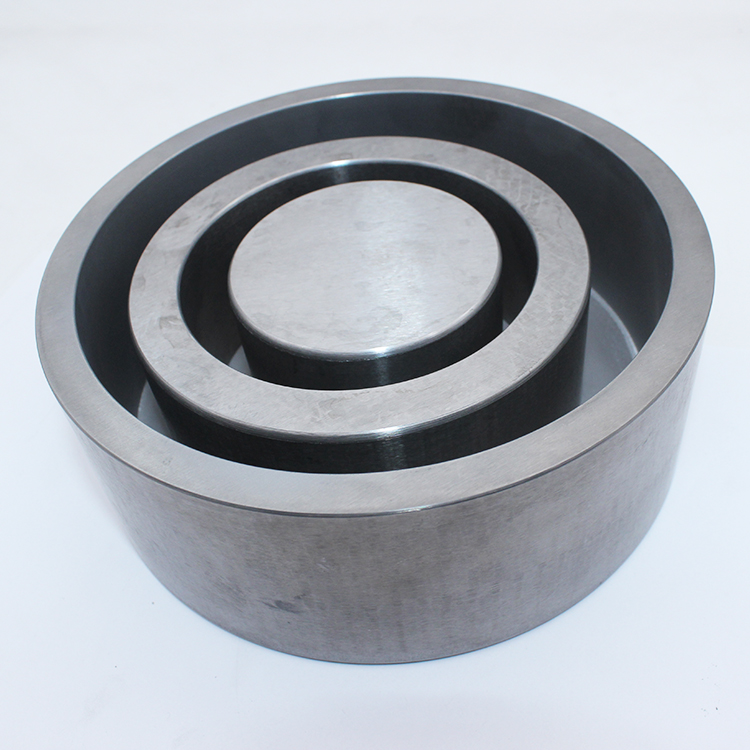

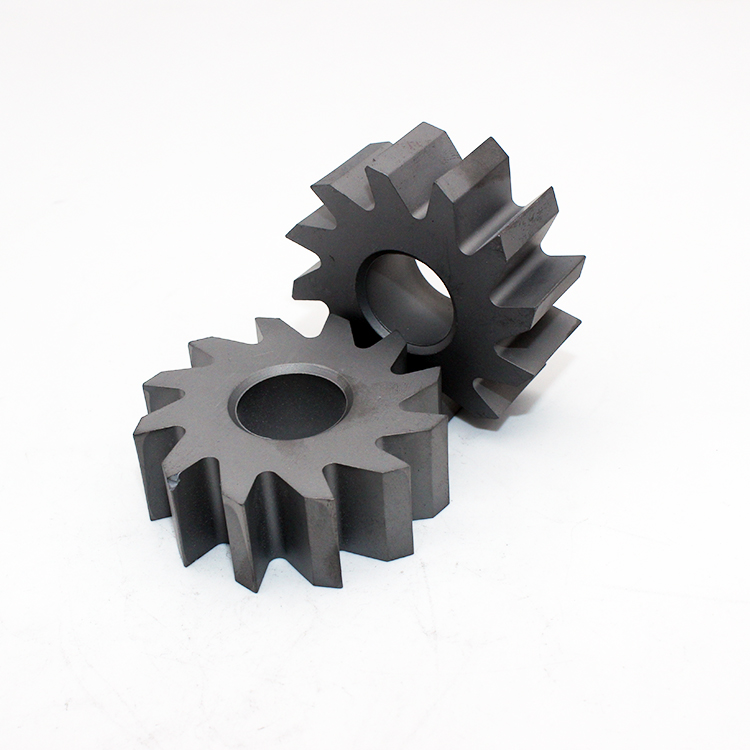

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

Product detail pictures:

Related Product Guide:

To continually enhance the management technique by virtue of your rule of "sincerely, great faith and high-quality are the base of company development", we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for Manufactur standard Internal Scarfing - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu , The product will supply to all over the world, such as: El Salvador, Zambia, Latvia, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

We not only will try our best to offer superb solutions to every single shopper, but also are ready to receive any suggestion offered by our prospects for Manufacturer for China Precision Carbide Auto Metal Machinery Stamping Parts, Welcome all clients of dwelling and abroad to go to our corporation, to forge a fantastic long term by our cooperation.

Manufacturer for China Precision Stamping, Metal Stamping, We always insist on the management tenet of “Quality is first, Technology is basis, Honesty and Innovation”.We are able to develop new products continuously to a higher level to satisfy different needs of customers.

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for Best Price for China Custom Precision Tungsten Carbide Steel Resistance Machine Parts, We are one of the largest 100% manufacturers in China. Many large trading companies import products from us, so we can give you the best price with the same quality if you are interested in us.

Best Price for China Punch Pin in Moulds, HSS Punch Pins, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We have been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products and solutions. For anyone who is interested in our company and items, you should make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We’ve been gonna usually welcome guests from around the globe to our corporation. o create small business relations with us. You should definitely feel no cost to speak to us for enterprise. nd we believe we’re likely to share the most effective trading practical experience with all our merchants.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.