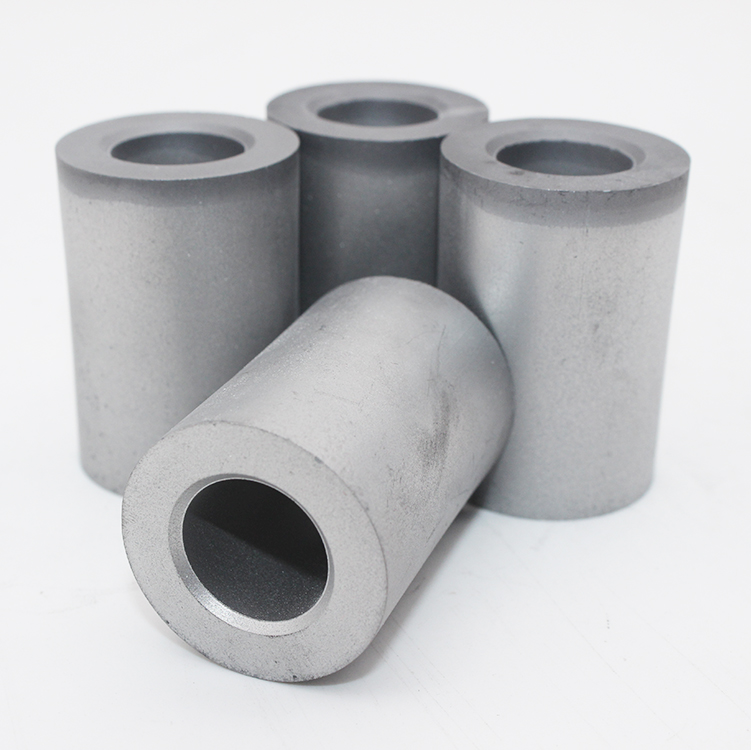

High Quality Tungsten Carbide Mold Parts – Customized Tungsten Carbide Cold Heading molds/punch dies/wire drawing dies – Zhongfu

High Quality Tungsten Carbide Mold Parts – Customized Tungsten Carbide Cold Heading molds/punch dies/wire drawing dies – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Model Number:

-

mold

- Shaping Mode:

-

Die Casting

- Product Material:

-

Steel

- Product:

-

Vehicle Mould

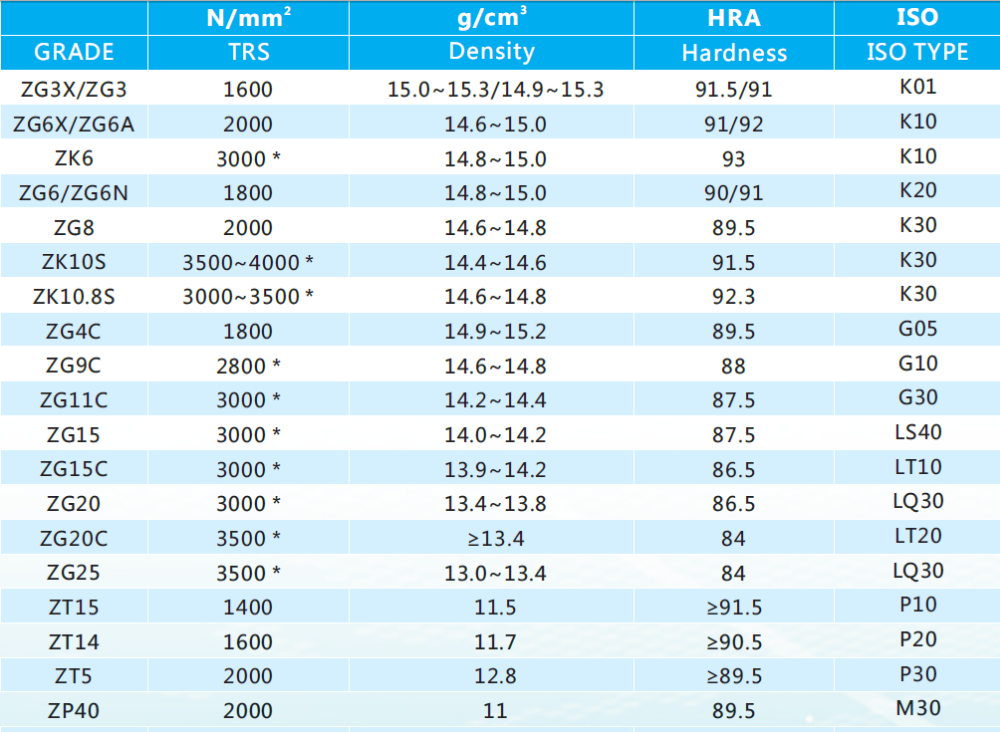

- Grade:

-

ZG6X

- Material:

-

Tungsten Carbide

- Certification:

-

ISO 9001

- Color:

-

Silver Grey

- Size:

-

Customized Size

- Service:

-

OEM ODM

- Packing:

-

Poly Bag + Inner Box + Carton

- Quality:

-

High Quanlity

- Usage:

-

Industrial Field

- Weight:

-

Size Requir

Many fasteners are formed using cold heading dies. The cold heading die is subjected to severe stamping loads, and the surface of the die is subjected to high compressive stress. The mold material is required to have high strength, toughness and wear resistance.

After the cold heading die is heat-treated, the surface must have high hardness and the core must have good toughness, so that a certain compressive stress on the surface can offset the stress suffered during the cold heading process. Many fasteners are formed by cold upsetting molds. The cold heading die is subjected to severe stamping loads, and the surface of the die is subjected to high compressive stress. The mold material is required to have high strength, toughness and wear resistance.

In metal pressure processing, the metal is forced through the die under the action of external force, the cross-sectional area of the metal is compressed, and the tool that obtains the required cross-sectional area shape and size is called a wire drawing die. The wire drawing die is a very important and consumable die used by various metal wire manufacturers (such as wire and cable factories, steel wire factories, electrode welding wire factories, etc.) to draw wires. The wire drawing die has a wide range of applications, mainly used for drawing straight and difficult-to-machine objects such as bars, wires, wires, pipes, etc. It is suitable for drawing processing of metal and alloy materials such as steel, copper, tungsten, and molybdenum. Since the cost of the wire drawing die accounts for more than 1/2 of the wire drawing cost, how to reduce the cost of the wire drawing die and increase its service life is an urgent problem for metal wire production units to solve.

Stamping die is a special process equipment for processing materials (metal or non-metal) into parts (or semi-finished products) in cold stamping processing, called cold stamping die (commonly known as cold stamping die). Stamping is a pressure processing method that uses a mold installed on a press to apply pressure to the material at room temperature to cause separation or plastic deformation to obtain the required parts.

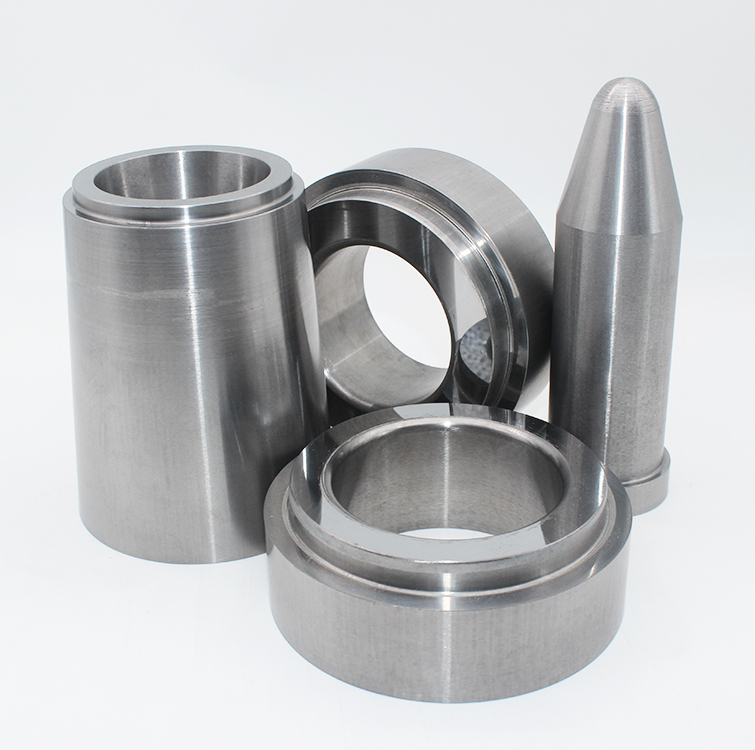

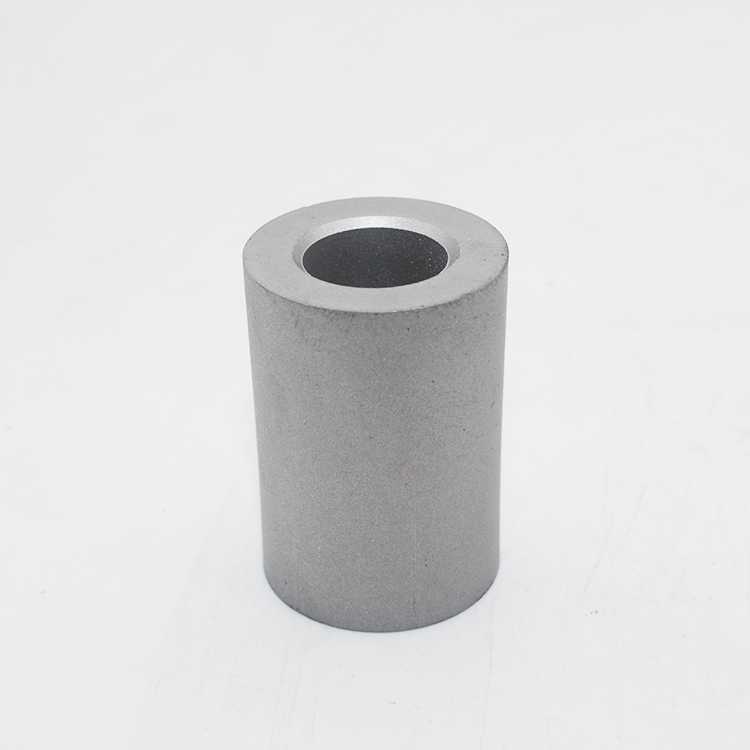

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for High Quality Tungsten Carbide Mold Parts – Customized Tungsten Carbide Cold Heading molds/punch dies/wire drawing dies – Zhongfu , The product will supply to all over the world, such as: Bangladesh, Denmark, Turin, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly