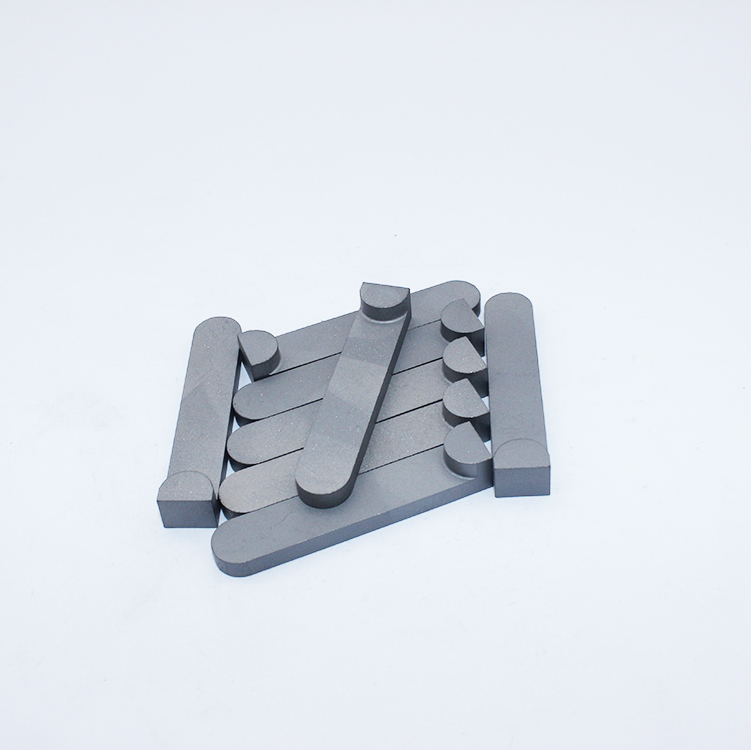

Competitive Price for Carbide Grinding Machine - Tungsten carbide tamping tines use tip wearing part for Railway Industry – Zhongfu

Competitive Price for Carbide Grinding Machine - Tungsten carbide tamping tines use tip wearing part for Railway Industry – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

PETORY

- Model Number:

-

tamping tines for railway

- Product name:

-

tamping tines

- Usage:

-

for railway

- leadtime:

-

in stock

- Grade:

-

YG9C

- Size:

-

Customized Size

- Color:

-

Silver Black

- Service:

-

ODM OEM

- Certification:

-

ISO 9001

- Samples:

-

Avaliable

- Packing:

-

Box

|

Item

|

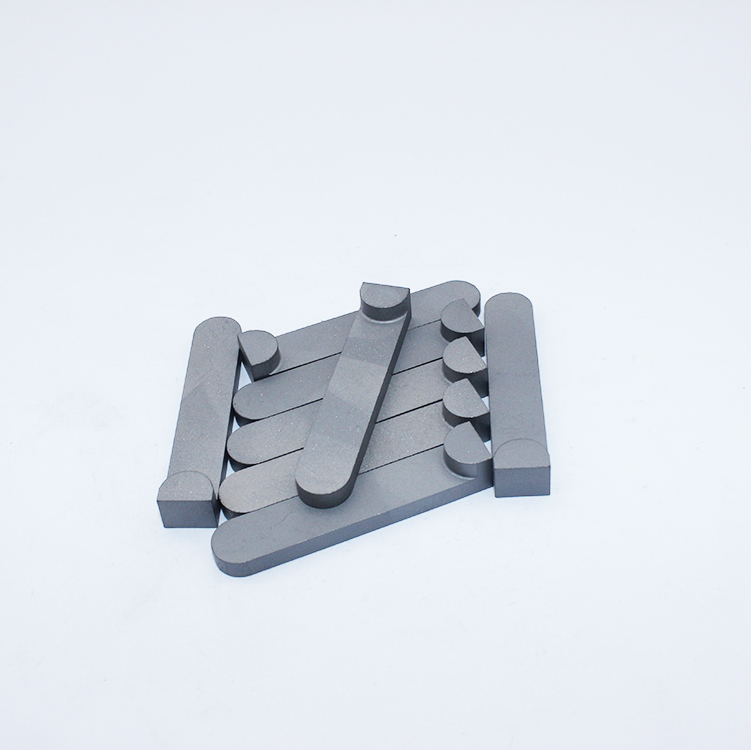

Tungsten carbide tamping tines

|

|

Sizes

|

customized or standard

|

|

Country of Origin

|

Jiangxi, China

|

|

Usage

|

Tungsten carbide tamping tool, tamping pick

|

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top.

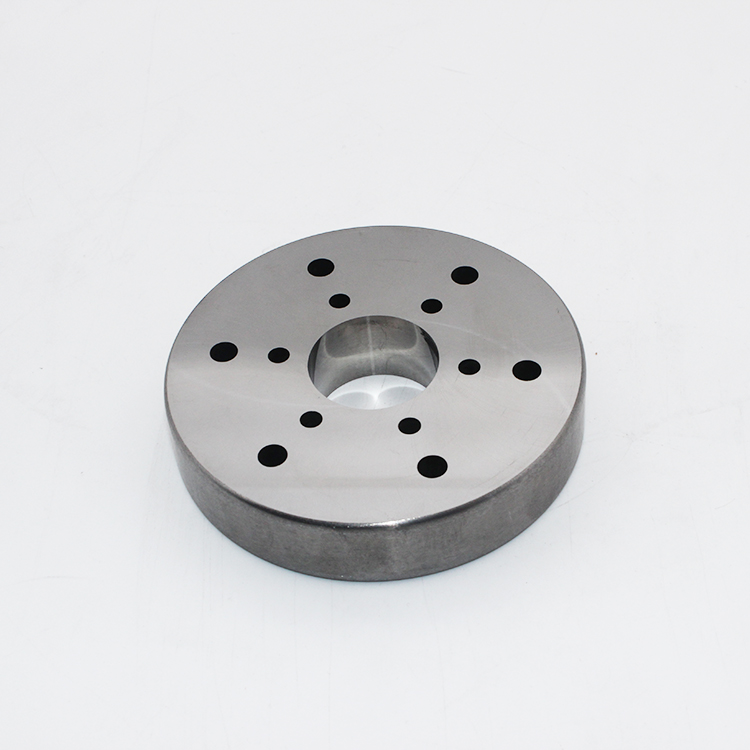

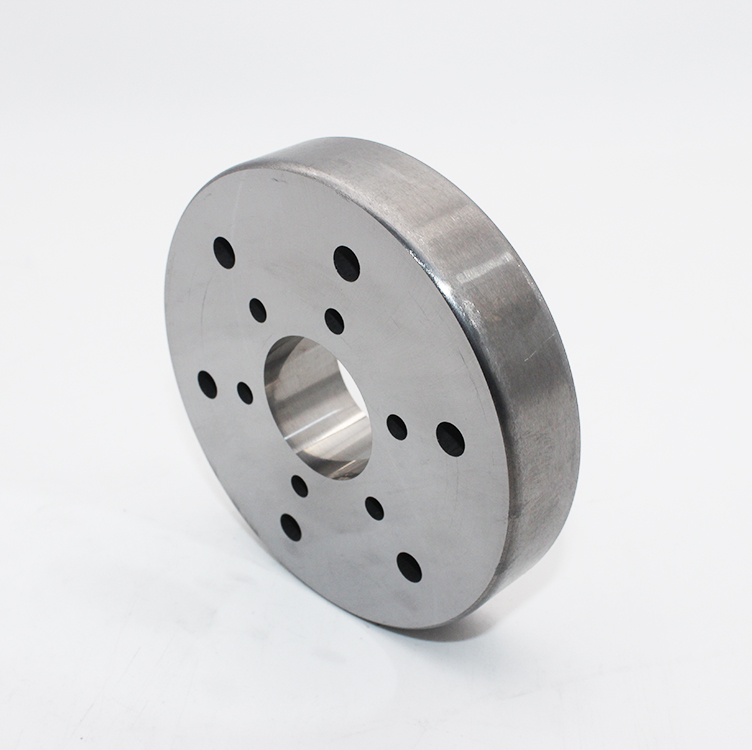

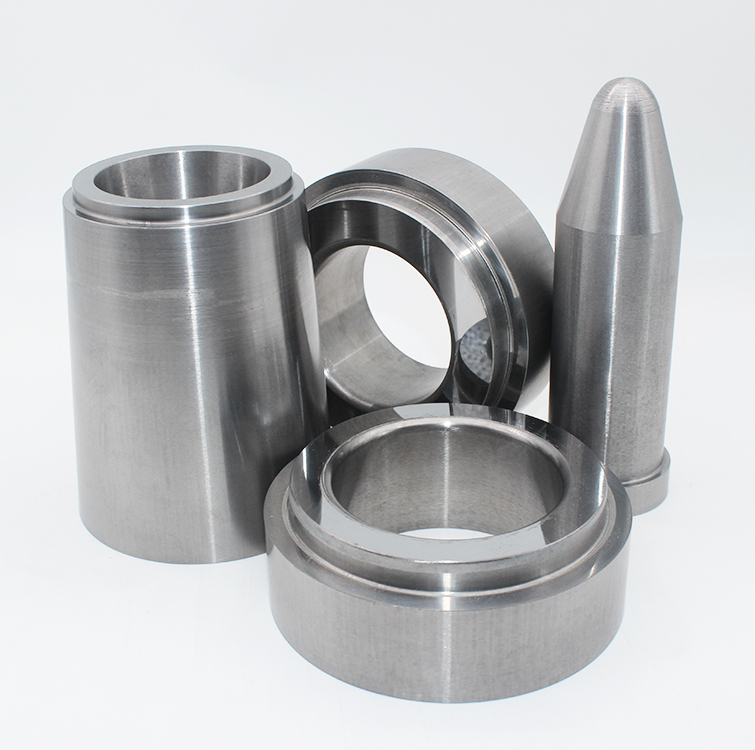

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Competitive Price for Carbide Grinding Machine - Tungsten carbide tamping tines use tip wearing part for Railway Industry – Zhongfu , The product will supply to all over the world, such as: United States, Mali, Guinea, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.