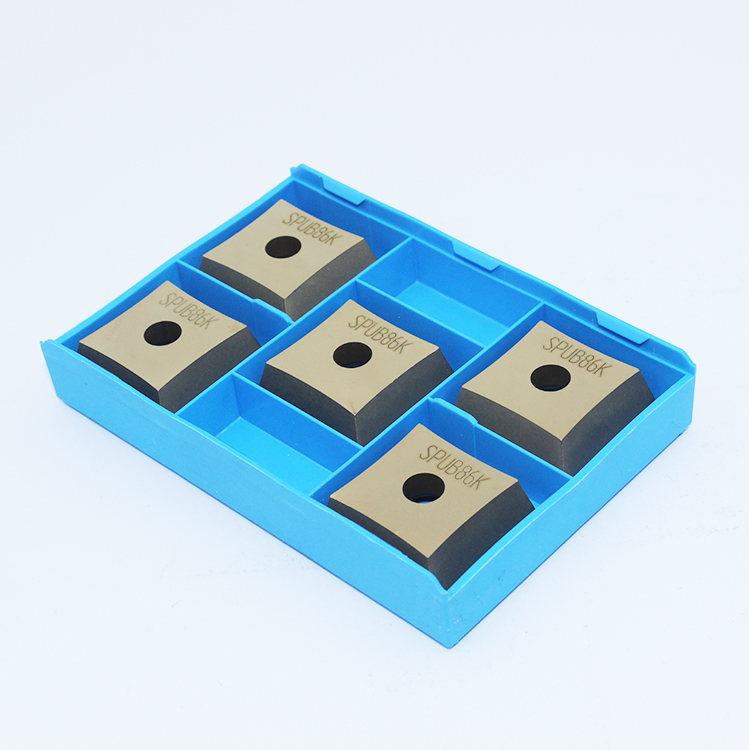

2021 Good Quality American Tool - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu

2021 Good Quality American Tool - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu Detail:

- Place of Origin:

-

Jiangxi, China

- Brand Name:

-

petory

- Model Number:

-

scarifier cutters

- Material:

-

Carbide, Tungsten Carbide

- Coating:

-

Tin

- Color:

-

Black

- Service:

-

OEM ODM

- Certificate:

-

ISO 9001

- Types of CNC Cutting Tools:

-

scarifier cutters

- surface:

-

smooth

- Size:

-

Customer’s Drawing

- Quality:

-

Top High

- Packing:

-

Wood

- Advantage:

-

High Wear Resistance

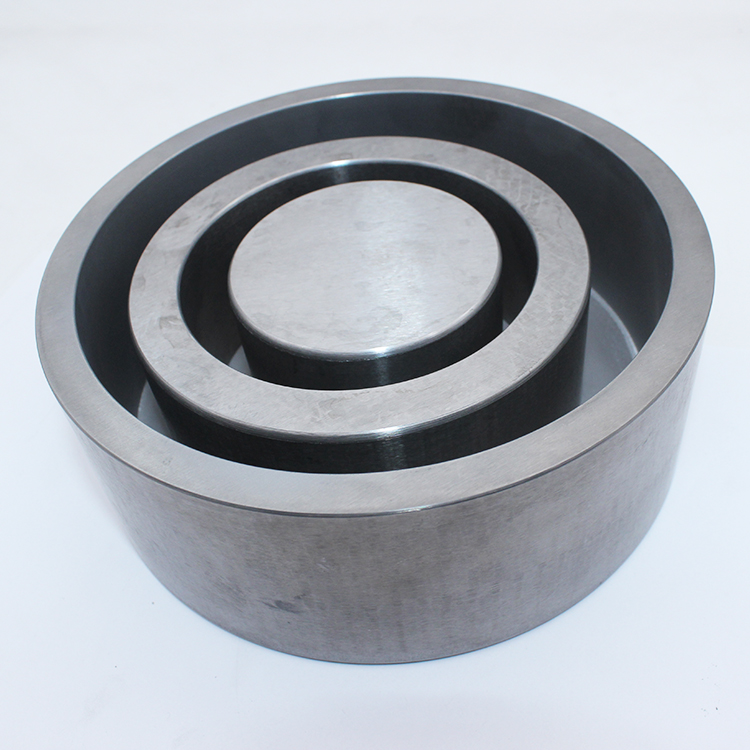

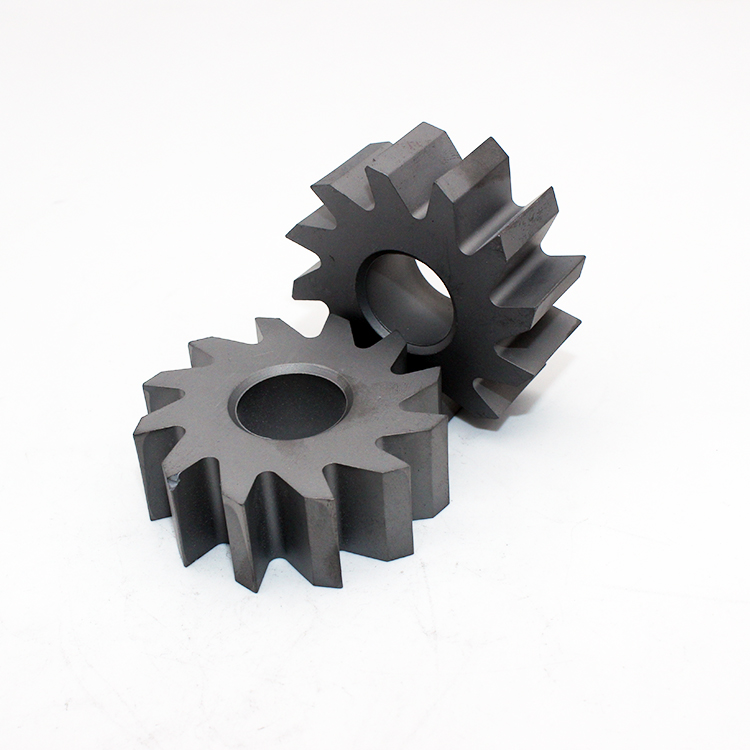

There are many narrow grooves on the tooth surface to form the cutting edge, and the gear-shaped gear machining tool is used to machine the workpiece according to the principle of helical gear meshing. During processing, the tool cuts beard-like fine chips from the tooth surface of the gear, so it is called a gear shaving cutter. Gear shaving cutters are used for finishing gear teeth after gear hobbing and gear shaping (see gear processing). The commonly used disc-shaped gear shaving cutter is like a hardened helical cylindrical gear (Figure 1). The groove on the tooth surface has two forms: one is that a circular or spiral pass is opened on the entire gear ring. The cross section of the groove can be rectangular or trapezoidal. This shaving cutter only sharpens the front face (groove) after being blunt. It is suitable for shaving cutters with modulus less than 1.75 mm; the other is that the grooves on both sides are impassable, which are inserted separately with comb-shaped inserts. In order to make the inserts can withdraw the knife, it is placed at the root of each tooth. Drill slanted holes. After this kind of shaving cutter is blunt, it needs to regrind the tooth profile and the cylindrical surface of the tooth top. Shaving knife

In order to reduce the cutting load of each tooth, the number of teeth of the gear shaving cutter is large, and the prime number is generally used to avoid a common factor with the number of teeth of the gear to be cut, otherwise the error of the gear shaving cutter will be copied to the gear to be processed. According to international standards, the precision of gear shaving cutters has three types: AA, A and B. In actual production, the gear tooth profile shaving with the correct involute tooth profile shaving cutter often deviates from the correct involute line near the pitch circle of the gear, and is recessed inward, with a deviation of about 0.01 to 0.03 mm. The tooth profile deviation of spur gears is larger than that of helical gears. In order to get the correct involute tooth profile of the workpiece, the tooth profile of the shaving cutter should be corrected. In mass production, the tooth profile correction curve of the shaving cutter is determined by experimental methods.

The gear shaving cutter can process straight and helical inner and outer cylindrical gears, with high production efficiency and smooth surface. In addition, there are also worm gear shaving cutters for processing precision worm gears. The type and parameters of the basic worm gear should be the same as the working worm gear matched to the worm gear. Like the gear shaving cutter, it has many narrow grooves on the spiral surface to form the cutting edge and contain the chips. Worm gear shaving cutters are difficult to manufacture and are only used when machining worm gears that require high precision.

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for 2021 Good Quality American Tool - China best price custom tungsten carbide steel cutters concrete scarifier blade – Zhongfu , The product will supply to all over the world, such as: Washington, Saudi Arabia, Zimbabwe, If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Rapid Delivery for China 1 Set 10PCS Tungsten Carbide Insert and Screw for Hand-Held Woodworking Tool, Customer pleasure is our main purpose. We welcome you to definitely build business relation with us. For further more information, you should never wait to contact with us.

Rapid Delivery for China Carbide Insert, Woodworking Tool, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for 2019 High quality China Long Life Tungsten Carbide Milling Shoulder Inserts Apkt1003pdr-F2, We’ve been searching ahead to building positive and helpful links with all the providers within the planet. We warmly welcome you to definitely get in touch with us to begin discussions on how we are able to bring this into being.

2019 High quality China Cemented Carbide, Milling Inserts, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.